Suche

Company locations

The whole picture – with just a single click. Find out here where our branches are located, what services they offer and how to contact them.

REMONDIS Group locations

Discover the world of REMONDIS with its approx. 900 branches and associated companies in over 30 countries across Europe, Africa, Asia and Australia.

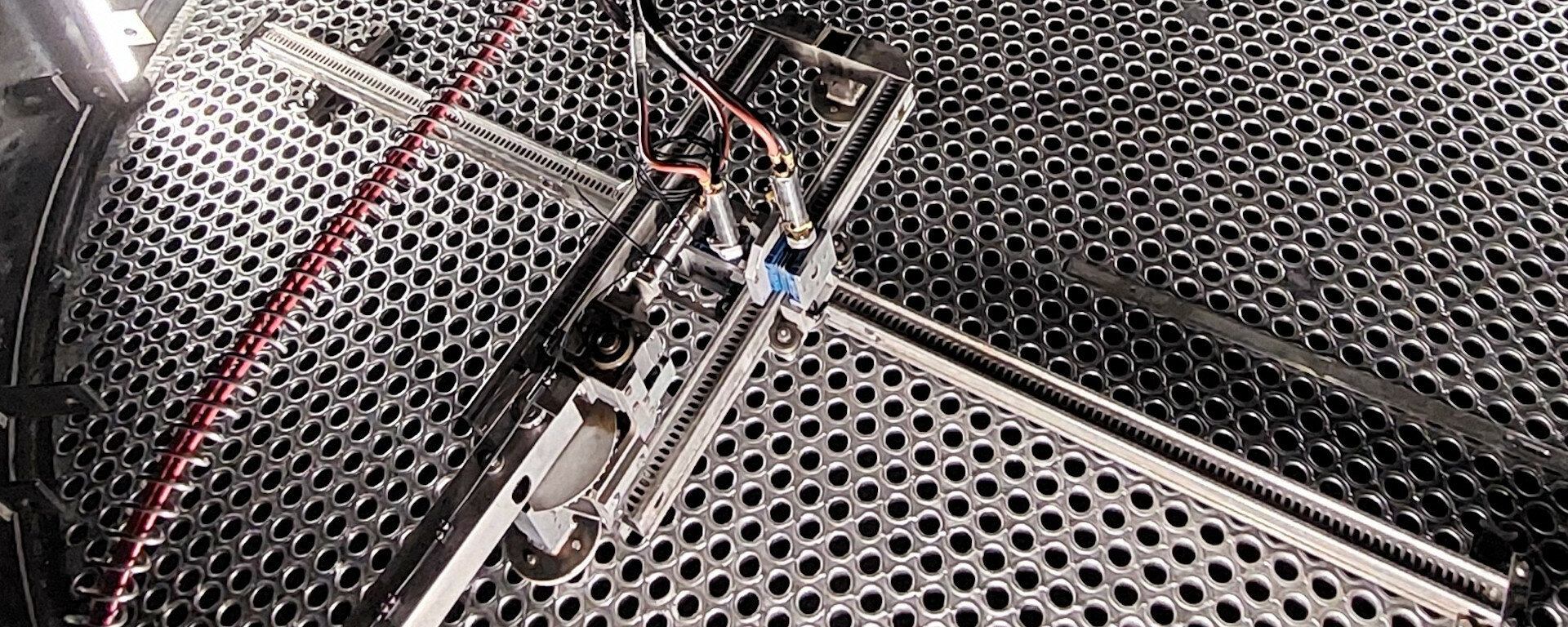

Progress in industrial cleaning: With a remote-controlled cleaning technique, the experts from BUCHEN UmweltService were able to remove contamination in the reactor more safely, better and more efficiently

If stationary shell-and-tube reactors have to be cleaned, this is usually an elaborate undertaking. Specialists enter the reactor under high safety precautions and remove contamination in the narrow interior with hand-guided high-pressure spirals. Since the manual work is very strenuous, the teams usually have to be changed quickly. This requires a correspondingly high level of personnel deployment.

Trend-setting technology is simply part of our services. After all, it's about ensuring an innovative range of services with maximum customer benefit.

Werner Fischerbauer

Head of Industrial Services

Safer, more efficient, more powerful

During the overhaul of a chemical plant in southern Germany, BUCHEN UmweltService now used an automated solution for the first time to clean the tube bundle reactor. The focus was on a bundle-positioning unit that can independently clean the inside of the reactor. The unit is controlled from outside and continuously transmits images from the reactor interior with its integrated camera system. Because the skilled workers no longer carry out the cleaning processes themselves, but direct them from a distance, their work has become easier and, above all, safer. In addition, optimised cleaning results can be achieved through automation.

For example, the remote-controlled technology enables the feed speed of the high-pressure spirals to be adapted to the degree of contamination. Such uniformity is not possible with hand-guided spirals. In addition, the cleaning unit can be positioned extremely precisely even under unfavourable environmental conditions. Splash water, steam or high humidity - factors that cause fogged-up safety helmet visors and limited visibility during manual operation - hardly play a role due to the powerful camera technology.

For plant operators as well as for the teams of skilled workers, the automated process opens up decisive advantages in terms of safety, efficiency and performance. Modern application technology is simply an ideal way to keep making progress in industrial cleaning.

As one of the leading industrial service companies in Europe, BUCHEN relies on automated technologies and processes, including numerous in-house developments. See the AIC robot (Automated Industrial Cleaning) in action.