Find out more about HYDROMATE in the article ‘High-tech for industrial cleaning’.

Rules

Only words with 2 or more characters are accepted

Max 200 chars total

Space is used to split words, "" can be used to search for a whole string (not indexed search then)

AND, OR and NOT are prefix words, overruling the default operator

+/|/- equals AND, OR and NOT as operators.

All search words are converted to lowercase.

Company locations

The whole picture – with just a single click. Find out here where our branches are located, what services they offer and how to contact them.

REMONDIS Group locations

Discover the world of REMONDIS with its approx. 900 branches and associated companies in over 30 countries across Europe, Africa, Asia and Australia.

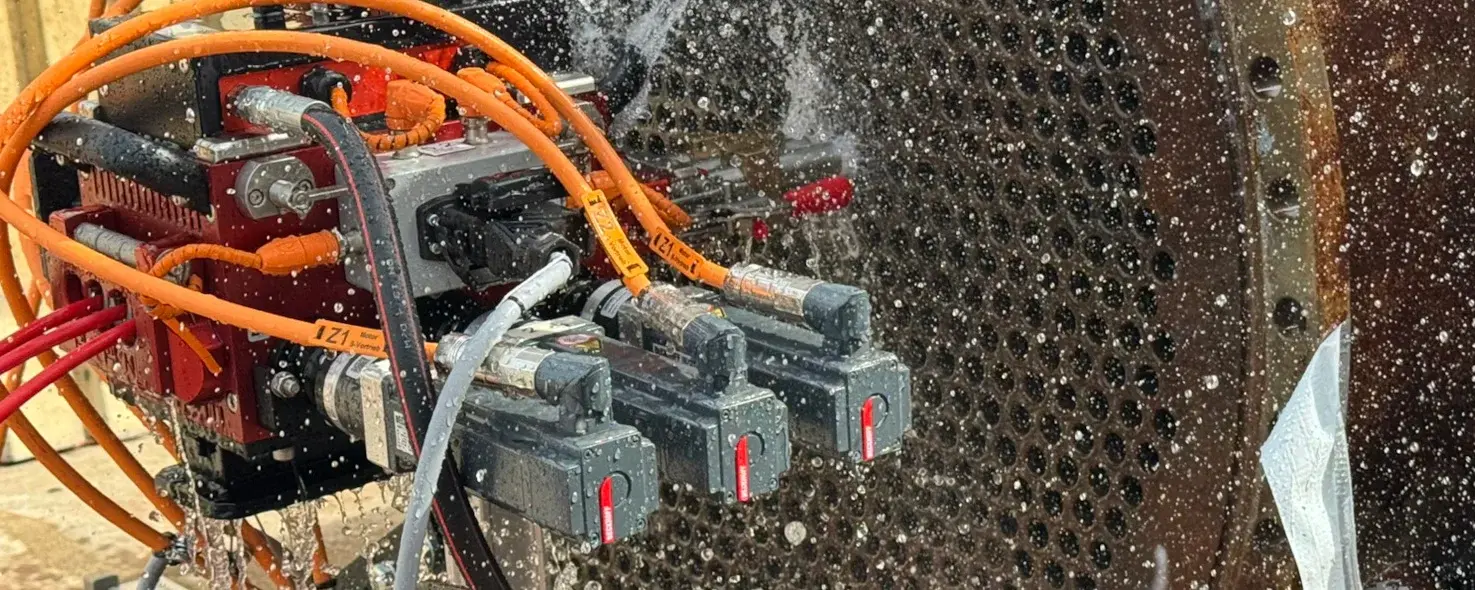

Fully automated rather than manual, constant, recorded cleaning quality and greater staff safety: the HYDROMATE® has taken the way the inside of heat exchangers is cleaned to a new level – a technology that is unique and a world first.

Heat exchangers are essential for industrial heating and cooling systems. Cleaning the inside of these machines, however, is a complex task. The HYDROMATE® has revolutionised this process: it cleans them in a methodical and precise way without the need for manual intervention – a fully automated and effective system. The result: the heat exchangers continue to perform efficiently and the work and potential risks for the operatives are minimised.

HYDROMATE®: Faster. Smarter. More efficient.

With a clear focus on practicality and efficiency, BUCHEN UmweltService developed this mobile system specifically for industrial cleaning. Just like conventional systems, the HYDROMATE® uses high-pressure water technology for interior cleaning – but it does so more intelligently. The system automatically calculates the cleaning paths, whether horizontal or vertical. This means maximum process reliability, reproducible results and consistently excellent cleaning quality.

High-pressure cleaning made easy and safe

Instead of using manual high-pressure water hoses, employees can control the cleaning process easily and safely from a distance using radio remote control. The system is set up and monitored automatically via a tablet. The core components of the HYDROMATE® are the individually controllable high-pressure hose lines with servo motors. These enable high-precision hose advancement, individually for each pipe – this increases cleaning efficiency and ensures maximum process reliability.

HYDROMATE®: A few facts & figures

- 100% fully automated heat exchanger tube cleaning system

- High tractive force for each high pressure hose

- Highly precise individual hose propulsion with a servo motor

- AI-based image processing to capture the actual hole pattern

- A step towards Industry 4.0

The details – how it works:

- The heat exchanger’s key data is put into the system.

- The system calculates the hole pattern of the tube sheet.

Alternatively: a photo or drawing of the actual hole pattern is processed by an AI-based image processing program. - The jet trajectories are generated.

- A remote-controlled ‘teaching procedure’ is carried out to determine the software end positions.

- The fully automated cleaning process begins – options: tube cleaning, rinsing program or cleaning the surface of the tube sheet.

- The system draws up a cleaning report at the end. Everything is automatic.

An innovator: pioneering developments to grow market success

BUCHEN UmweltService’s HYDROMATE® is neither its first groundbreaking development in the industrial cleaning sector nor its last. Why? Because the company systematically pursues all technological opportunities to automate systems and make big strides towards Industry 4.0.

With around 20 patents and registered designs, the company is continuously setting new standards. In the spotlight: automated high pressure cleaning processes with remote-controlled machinery.

“As far as we are concerned, development is not simply a technological challenge. It’s also about realising a vision. It is great to create a product that really simplifies everyday industrial tasks and pushes efficiency to a completely new level.”

Branislav Radu

Head of Technology, BUCHEN UmweltService

branislav.radu@buchen.net

The future needs innovations

Working on around 30 new developments or further developments every year, it is the company’s own technology department that drives these developments. By doing so, BUCHEN UmweltService is systematically moving the industrial cleaning sector towards the future.

Read more about automated cleaning of a tube bundle reactor here.